WHAT IS THERMOFORMING?

Thermoforming is the name of a technological process in which products of specific shapes are formed from flat films or sheets, preheated to a specific temperature, characteristic of the material. Another common name for thermoforming is “vacuum forming”. Relatively inexpensive and highly efficient processing makes thermoforming widely used for both packaging and technical components. Thermoforming technology is used in almost all industries: from food through furniture, automotive, electrical engineering, gardening to cosmetics, pharmaceuticals, etc.

Our predominant production is:

• Trays for external and internal transport

• Box inserts

• ESD technical components used in the electronics industry, among others

• Vehicle interior components

• Custom Clamshells / Blisters (Stock)

• Blister packaging (sealed or resealable)

We provide thermoforming services from materials such as:

ABS and HiPS – materials resistant to external factors, non-flammable and slow-burning, resistant to chemical agents, to low and high temperatures, with different surface conductivity of current

PET RPET and PVC – highly transparent materials for blister packs, trays, inserts, and clamshells.

TYPES OF PLASTICS

Utilizing our extensive technical background and experience in thermoforming from the following materials.

• ABS

• HIPS

• PVC

• PET, RPET, A-PET, PET-G

We also offer thermoforming of ESD materials with specific resistance, materials with protective barriers like EVOH, as well as laminated films, such as: PET/PE and others. We also offer thermoforming from recycled plastic RPET.

DESIGN AND TOOL SHOP

Our Design Office and Tool Shop have the best tools on the market. Both CAD/CAM software and high-end CNC machine tools allow us to take on difficult technological challenges.

For special tasks we also use 3D scanning technology, as well as prototyping of mouldings and stampings on 3D printers.

We are constantly developing our Tool Shop by investing in machinery and the support of our engineering team, allowing us to participate in many specialized projects. Close cooperation of the Design Office with the Tool Shop and Production gives the possibility of fast implementation of new elements into production.

What is a Blister?

Pair text with an image to focus on your chosen product, collection, or blog post. Add dBlister pack is formed as a result of heating the material and giving it a proper shape set by the mould. Another term for blister commonly used is stamping or moulding.

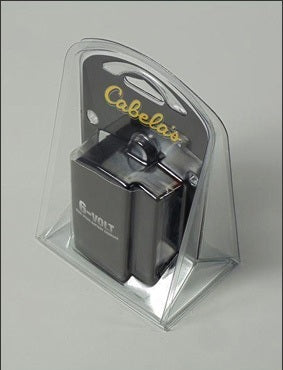

It is a product made with thermoforming technology. For the production of blister packs, transparent films, mainly PET and PVC, are most often used due to the possibility of an elegant exposition of the packed product. The possibility of sealing a blister with a box or foil protects goods against accidental opening or theft. For ecological reasons, the snap blister, made of homogeneous and easily recyclable material (PET, PVC) or a blister sealed with another blister or foil of the same type, is becoming more and more popular.

Blister packs are very popular and can be found in practically every market segment. Batteries, toothbrushes, metal items (screws, nails, nuts), cosmetic items (lipstick, mascara, etc.), school supplies, toys, and more are packaged this way.etails on availability, style, or even provide a review.

What is A Clamshell?

A clamshell is a one-piece container consisting of two halves joined by a hinge area which allows the structure to come together to close. Clamshells can be made to be reusable and reclosable or can be sealed securely.

It is a product made with thermoforming technology. For the production of clamshells, transparent films, mainly PET and PVC